Our hydraulic shears, also known as crop shears or cut-to-length shears, can be used to cut strips and sheet bars made of different steel and metal alloys or to separate different kind of plastic applications.Fiber composite materials, such as CFRP and GFRP, can also be easily cut with the hydraulic shears manufactured by the hpl-Group. Whether for sheet metal preparation before pressing, for cutting narrow strips at right angles to the strip flow direction or for use in strip cutting and prefabrication workshops for various production plants, the hydraulic shears manufactured by the hpl-Group are designed for many applications.

Inaccurate strip head and strip tail ends can be removed and the strip running from decoiler to recoiler can be cut to defined lengths.

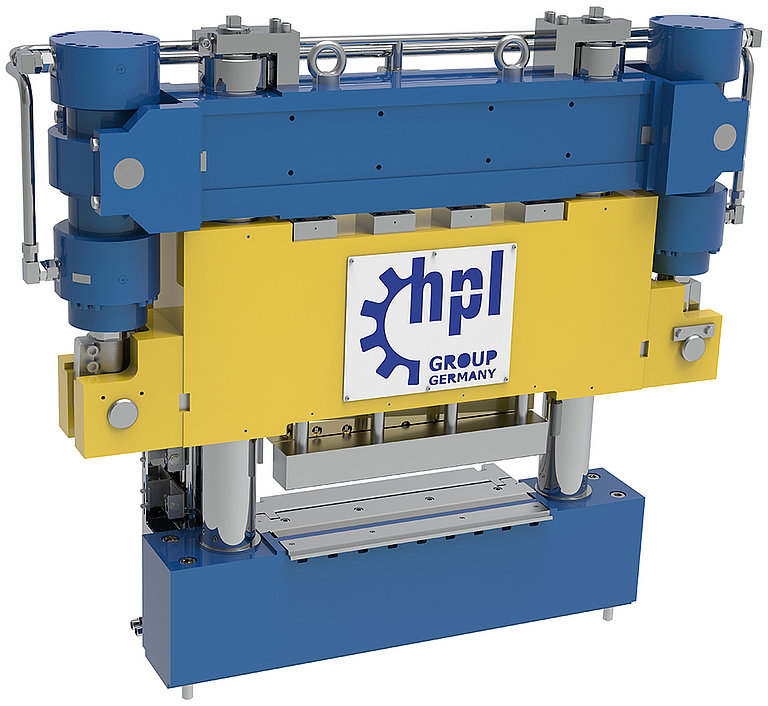

hpl standard shears are available with cutting widths, i.e. width of the cutting edge, of 450 mm, 850 mm and 1350 mm.

The designed aggregates can be used to cut material thicknesses ranging from 0,5 mm to 6,0 mm. In case of large thickness variances, the cutting gap can be adjusted manually or fully-automatically to minimize wear on the cutting edges.

All hydraulic shears have a modular design that allows an easy retrofit of hydraulic actuators, additional anti-lowering means as well as extension devices for an ergonomic knife change, if required.

Because of their symmetrical construction and the uniform knife holding mechanism, the upper and the lower knife both have four (4) cutting edges ensuring a long service life of the cutting tools and, thus, saving money. The knives are wear-resistant and made of high-quality tool steel.

The hydraulic system of the shear is designed to operate within the common pressure range of approx. 100 – 120 bar. If higher cutting forces are required, a pressure booster is used to avoid complex and, above all, expensive high-pressure hydraulics.

All safety-relevant functions are equipped with additional shut-off valves ensuring that with the achieved Performance Level D a high reliability of the integrated safety functions is realized, regardless of whether the machine is operated manually or automatically integrated into the control unit.

If required, we will assist you preparing the risk assessment for the mechanical and electrical integration of the hydraulic shear into your line concept.

If requested, the strip connector can be delivered with all required sensors, valves and pre-wired to terminal box.

Siegbert Plasger

Sales „Hydraulic Shear“

Phone: +49 5944 9301-130

E-mail: Siegbert.Plasger[at]hpl-group.de