Slitting Lines / Cut-to-length Lines

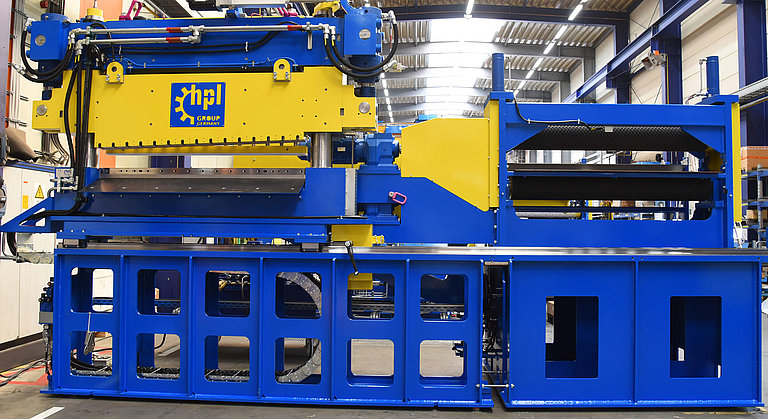

hpl Group designs and manufactures slitting lines as complete systems for all ferrous and non-ferrous metals as well as special materials with metallic or coated surfaces. We focus on slitting shears for hot rolled steel and shears for thin strips, offering our customers the best quality and highest possible productivity.

The decisive factors for an uncompromising quality in the cutting process of cold rolled strips are: adherence to narrow cutting tolerances, burr-free cutting as well as the precise recoiling of the cut strips. The slitting lines manufactured by the hpl Group therefore consist of highly specific precision shears especially designed for cutting thin metal strips all the way up to metal foils.

The high degree of precision in our slitting shears enables line speeds of up to 600 m / min at constant quality.

With our CNC thin strip slitters, we provide the thinnest stainless and copper foils - down to a minimum thickness of 0.02 mm. This slitting task requires extremely tight manufacturing tolerances as well as special measures for eliminating clearance between the machine elements. This results in parallelisms of the knife shafts and an extremely low axial run out of the shaft shoulders.

This slitter, running in Germany, cuts strips with a tensile strength of up to 2,300 N/mm2. Its maximum speed is 600 m/min. The maximum strip width is 450 mm.

The slitter works with or without steel ejector rings and a dancer roll system at its entry side.

For the safe removal of the trimming scrap at thin strip thicknesses, the line is equipped with a trimming scrap vacuum suction device.

![Längsteilanlage [Translate to Englisch:] Unsere Längsteilanlagen können mit mehreren Haspeln zur synchronen Bandaufwicklung ausgestattet sein.](/fileadmin/_processed_/a/6/csm_Slitting1-neu_b_4d799089fb.jpeg)

![Dünne Abisolierlinie Skizze [Translate to Englisch:] Typische Anordnung einer Längsteilanlage für Dünnblech](/fileadmin/_processed_/c/b/csm_thinstrippingline_59a363e5d0.gif)

![Stahlrumpf einer Längs- und Querteilanlage [Translate to Englisch:] Diese kundenspezifische Einheit wurde für eine Entgratung nach dem Schneidvorgang ausgelegt.](/fileadmin/HPL/images/Anlagen/Stahlrump6.jpeg)

![Bremsgerüst [Translate to Englisch:] Bis zu 30 Bänder können mit dieser Anlage geschnitten werden. Das schmalste Band ist 4 mm breit.](/fileadmin/HPL/images/Anlagen/Bremsgeruest-2.jpeg)

- In order to produce jumbo coils, our slitting lines can be supplemented with multi-coiling systems.

- Typical arrangement of a thin strip slitting line.

- This unit was tailor- made for de-burring after slitting.

- Up to 30 strips can be cut with this line. The smallest strip width is 4 mm.

- Re-coiling of slit coils with out-board bearing in order to avoid reel mandrel deflection.

- Our strip tension brake stands allow applying different strip tensions to different areas of the slit strips. A scratch-free and uniform strip tension built up is the result.

- Heavy gauge slitting line, strip width max. 1,800 mm, strip thickness up to 12 mm, running in Germany, commissioned in 2012.

Martin Aufdemkamp

Sales Slitting Lines

Phone: +49 5944 9301-120

E-mail: martin.aufdemkamp@~@hpl-group.de