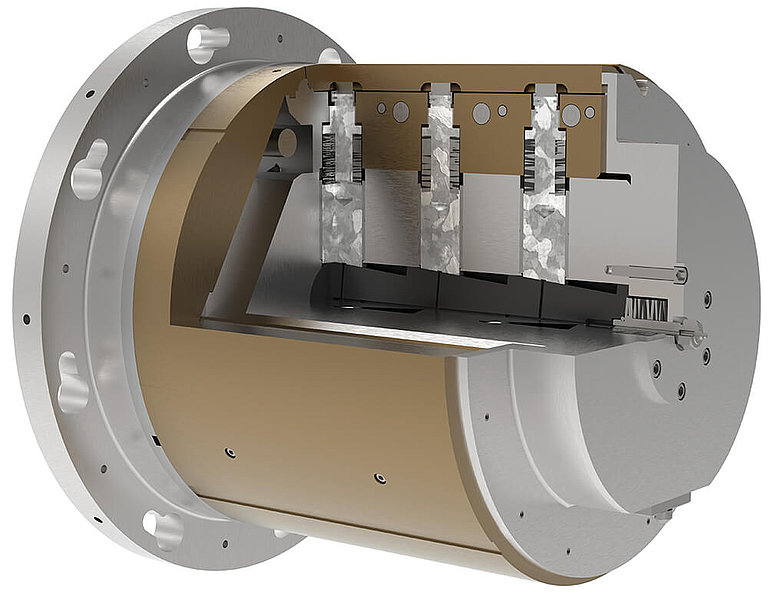

Hydraulic expansion shafts from the hpl-Group are mainly used as winding or reel shafts for the strip flow in the metal industry. The expansion or reel shafts are available in a variety of different designs. The units can be supplied in a three- or four-segment version; additional clamping mechanisms for the strip head end are optionally available.

The nominal outer diameters of the expansion shafts (=inner diameter of the customer material) can be supplied for all common diameters (Ø 200 – 800 mm) and strip widths (50 – 2.300 mm). Strip speeds and strip tensions to be realized must be specified jointly in order to ensure a smooth and uniform strip flow at all times. For applications with high tensile forces, hpl can easily integrate so-called support or counter bearings into your line.

Strip thicknesses ranging from 0,05 mm to 13,00 mm can be easily handled. For handling particularly thin and demanding material, the tensioning segments feature a meshed design so that the strip tail ends cannot interfere with the shaft mechanics.

All strip tensioning and winding applications are analyzed together with our customers, projected and then manufactured by the hpl-Group. Long-term experience in the field of expansion shafts and optimized manufacturing steps ensure, even for very large diameters, a concentricity of less than 0,2 mm in the mounted assembly group. All expansion segments are hardened and equipped with lubrication channels for reduced wear.

For line operation with different expansion shaft diameters, hpl offers attachment segments that can be manually screwed onto the reel shaft. The easy-to-use mounting rings ensure minimal change-over times.

We would be also happy to offer an alternating shaft solution for your line, in which the centering device on the expansion shaft is adapted to an existing holding fixture. This variant includes an additional calculation of the screw connection between the expansion shaft and the holding fixture.

The actuation for expanding and collapsing within a defined expansion range is hydraulically-operated in most applications.

For rotary applications, a hydraulic slewing ring as well as an actuating cylinder can be optionally supplied. These two units are hydraulically coordinated with respect to the clamping forces and actuation strokes.

You are free to choose our delivery scope for your individual production. We will be happy to deliver a package from a single source, ranging from the single configured expansion shaft without any accessories to the ready-to-use reel, including bearings and drive unit.

If required, we will assist you preparing the risk assessment for the mechanical and electrical integration of the expansion shaft into your line concept. It is particularly necessary to consider the safety when loading and unloading the goods during a line standstill, since the clamping forces must be temporarily ensured even when the protection area is accessible or emergency stop measures are engaged.

On request, we deliver the units with extended FEM analysis.

Martin Aufdemkamp

Sales „Hydraulic expansion shaft“ / Reel shaft

Phone: +49 5944 9301-120

E-mail: martin.aufdemkamp[at]hpl-group.de