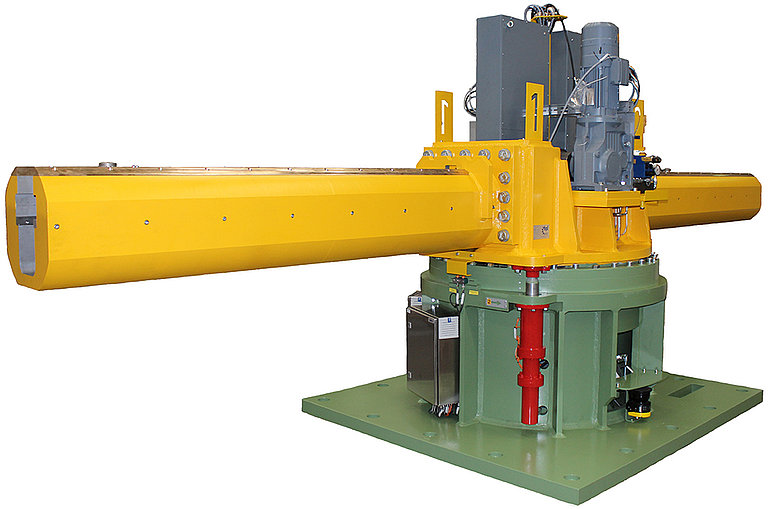

Our turnstiles are designed for coil handling with a total weight of max. 60 tons.

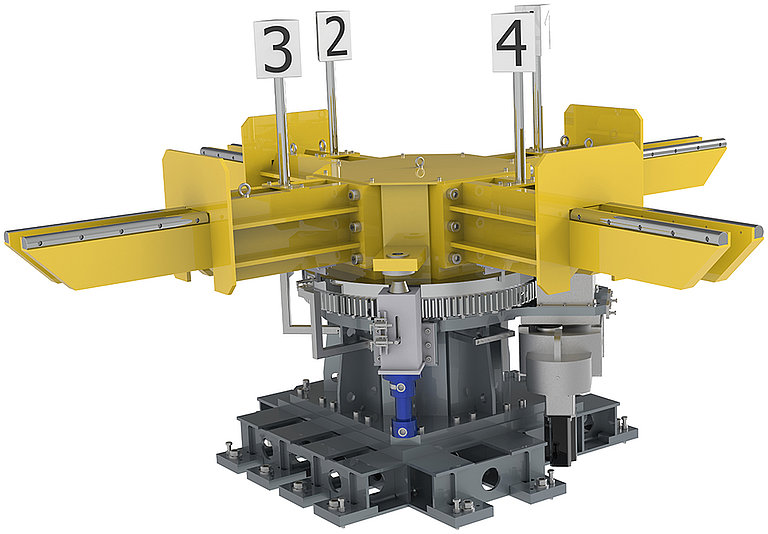

The 1- to 4-arm turnstile type(s) can be used to safely pick up coils and turn them over to peripheral line devices. For a quick and safe coil change, turnstiles are also often used as a buffer station or an intermediate storage area in order to reduce the time required for handling coils in the respective line area.

Our turnstiles consist of a solid base column, a slewing ring and the swiveling attachment with coil-carrying arms, incl. wear-resistant pads for a smooth positioning of the coil surface.

Because of the high transport weights, the slewing ring is driven by an electric gear motor. All operating positions are equipped with a safety locking unit to prevent unwanted movements of the coils when those are being picked up or put down. The motor can optionally be controlled via a frequency converter. By means of a sensor-assisted position determination, a speed and time-optimised rotation can thus be realised. Both the sensor-controlled creep speed function when persons or objects are entering the danger zone and the hydraulic safety locking unit ensure the operator safety at all times.

A special auxiliary module is the separation unit when handling multi-strip coils. This infinitely variable separation of coil strips, which can be integrated in the support arm, allows the strips to be taken off by a C-hook or coil car in a time-optimised manner.

All safety-relevant functions are equipped with additional shut-off valves ensuring that with the achieved Performance Level D a high reliability of the integrated safety functions is realized, regardless of whether the machine is operated manually or automatically integrated into the control unit.

If required, we will assist you preparing the risk assessment for the mechanical and electrical integration of the strip connector into your line concept.

If requested, the turnstile can be delivered with all required sensors, valves and pre-wired to terminal box.

Siegbert Plasger

Sales „Turnstiles“

Phone: +49 5944 9301-130

E-mail: Siegbert.Plasger[at]hpl-group.de