When machining the edges of narrow strips as for example after a slitting process, the shape of the strip edges is an essential part for many applications. On the one hand, no cutting burrs should arise; on the other hand, special applications require the strict observance of specified radii and the position of their vertices.

Experienced operators recognise by the flow of chips generated during the machining process if the edge contour corresponds to the specifications. This, however, includes a very high subjective influence. The machined edge contour can be assessed more objectively if a sample is cut at the end of the coil which is then examined, for example, under a transmitted light microscope. This method is very accurate but has the disadvantage of examining the edge shape only after a complete coil has been machined.

The new ConScan® system by the hpl-Group, a laser-based system for the visualisation of strip edge contours, allows the operator to intervene immediately in the production process in case of minor deviations from the specified contour. By displaying in real time the contour of all strip edges graphically on a screen typical defects, as for example burrs, edge chippings as well as radii and edges that are out of alignment, can already be visualised during the running production process. Tests show that even the smallest deviations such as minor edge chippings can be displayed clearly in full detail. This allows the operator to adjust the chip removal during the running production: the quantity of produced high-quality strips increases, production downtimes are avoided.

The system displays deviations from the target edge contour from approximately one-hundredth of a millimetre. In a further development stage, the deviations are measured and the measured values are directly incorporated into the knife positioning control.

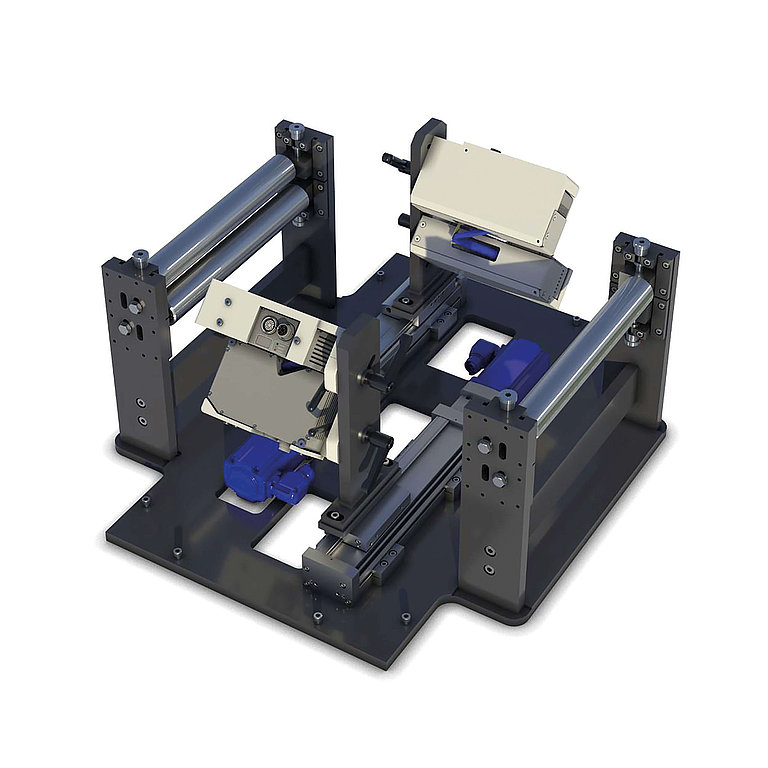

ConScan® is equipped with two laser sensors on each strip side. They project lines on the target edge which are detected by cameras mounted at a tilted angle. Their resolution is a few µm. Based on the course of the projected lines, the strip edge is calculated by the software and displayed on a screen.

The hpl-Group has developed ConScan® for strips from 2 to 200 mm wide and from 0.3 to 4 mm thick, which were previously cut in a slitting line. For example. Because of being only about 300 mm long in direction of the strip, the system can also be retrofitted into existing edge trimming lines.