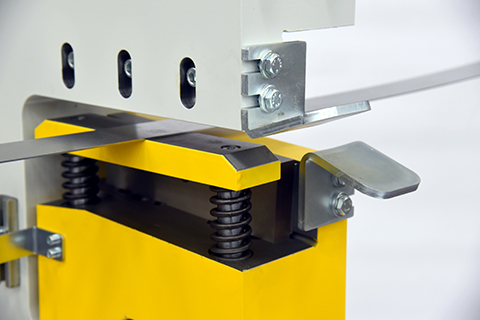

Shear blade change in less than 1 minute

Production downtimes in continuously running strip processing lines due to an unforeseen shear blade change do not only involve high costs, but also…

Added value for the steel industry

Genkinger GmbH and hpl-Neugnadenfelder Maschinenfabrik GmbH form a strong partnership within the Neuenhauser Group and offer customized complete…

Engineering data Klaus Bolender

hpl-Neugnadenfelder Maschinenfabrik GmbH is new owner of the innovative set of drawings developped by Klaus Bolender.

Goodbye to downtimes when changing shear knives!

hpl develops new cut-to-length shear that significantly reduces downtimes and enables shear knives to be changed in less than one (1) minute.

Line efficiency and operator-friendliness in focus

High machine utilization with optimum user-friendliness is our approach to the continuous further development of our standard products.

Safety First in Neugnadenfeld

Safety is a top priority at hpl-Neugnadenfelder Maschinenfabrik GmbH.

Real-time monitoring of strip edge contours

The new ConScan® system from hpl-Neugnadenfelder Maschinenfabrik visualizes the edge contour shape of narrow strips and thus enables immediate…

Pivoting wind vane transporter s-rb-t 300

"I need this third axis" - this key statement from our customer succinctly captures what distinguishes our new development from the field of hpl…

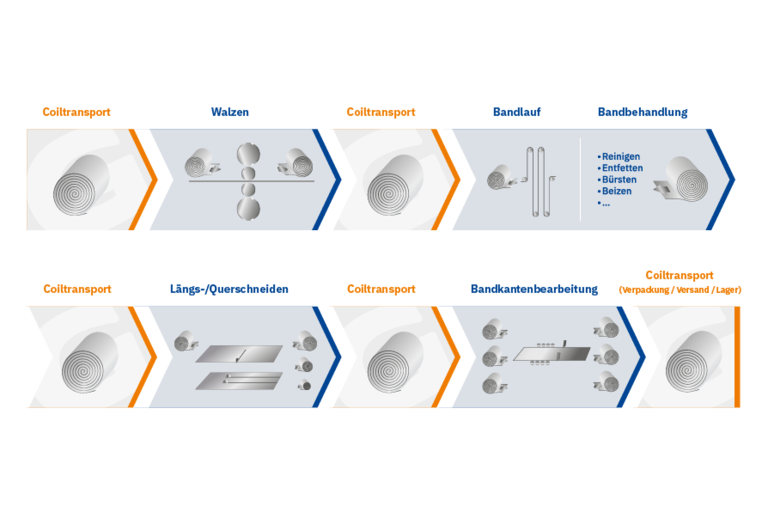

Advanced strip handling equipment from hpl-Group

The functional principle of a strip processing lines is similar to that of a cassette recorder, in which a tape is unwound from the supply reel, drawn…

Change in the management of hpl

At the end of 2020, the hpl-Group as specialist for strip processing and machining systems is under new management: Bernd Voshaar has passed on the…

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/f/3/csm_Bolender__Klaus_01_d7757496da.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/2/3/csm_Abtfaelschere_mit_Schnellwechselkassette_e35ef96d9a.jpg)

![[Translate to Englisch:] Laser-supported inline inspection of strip edges reveals minor contour deviations](/fileadmin/_processed_/7/f/csm_hpl_Conscan_Logo_blau_Unterzeile_3zu2_28eb56f7ff.png)